Managing the Machine Lifecycle for Your Rental Equipment

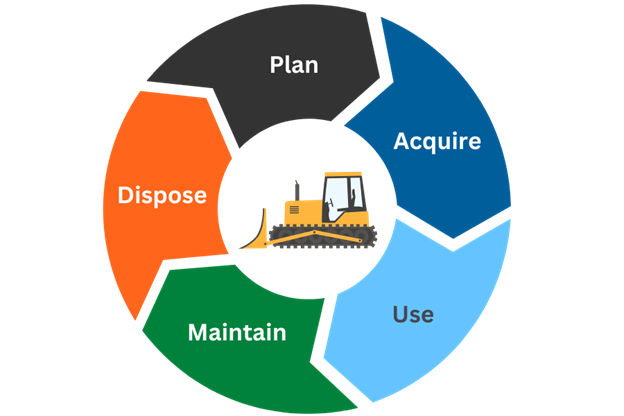

Every machine that you add to your fleet makes its way through a multi-step lifecycle. This cycle starts with the planning phase, before you’ve even purchased the equipment. From there, it runs all the way through the machine’s eventual disposal (and potentially even its replacement).

Optimizing your process for managing your machine lifecycle can help you maximize your return on every asset you add to your fleet. With appropriate planning and execution, you can strategically use your equipment budget to meet your long-term growth targets; keep each machine generating rental revenue as long as possible; and move on from aging assets before they become a drain on your resources.

All of this requires striking a delicate balance. The “sweet spot” will depend on the equipment type, your geographic location, and your company’s unique customer base. A successful equipment lifecycle management strategy will be based on YOUR real-world data, and will evolve over time to respond to the changing needs of your market.

The Five Stages of the Machine Lifecycle

Planning

The life cycle of a rental asset begins before you even add that asset to your fleet.

Of course, you’re not just buying equipment for the sake of buying equipment. You’re buying machines that your customers actually need – often – and are willing to pay profitable rates to rent. Ideally, you’re not just guessing at what’s needed; you’re making clear, fact-based purchasing decisions.

As you plan to add new assets to your rental fleet, ask yourself:

- Why is this machine needed? What need does it fill?

- Is this a new category or class for our business, or are we just adding a duplicate of an existing high-demand machine? For new assets, what might we not already know about servicing, supporting, or pricing it?

- What is our forecast for the total cost of ownership? What should we budget for parts and service? Will those numbers increase towards the end of the machine’s lifecycle?

- Is it smarter to purchase this equipment outright, finance it, or lease it?

- Is the equipment available immediately? What’s the expected lead time?

- How long do we anticipate renting out this machine? What rates are customers willing to pay? When do we expect to start turning a profit?

- When will we know it’s time to move the asset out of our fleet?

- What’s the expected resale value?

It’s common advice that past performance is not always indicative of future success, but data doesn’t lie. Your last 12 to 24 months of rental data can help you see what’s increased in demand – and what’s becoming less popular – for an optimal fleet mix. Consider which assets have the highest (and lowest) time or dollar utilization rates; which machines have been trending toward higher profits over the last several quarters; and which machines may be required for upcoming seasonal shifts.

Planning fleet additions through missed rentals and re-rentals

Tracking missed rentals is an excellent way to shape your equipment lifecycle management strategy. Each time a sales team has to tell a customer they don’t have a specific item available for rent, add it to a Missed Rentals list. At the start of each new equipment planning cycle, refer to this list of potential targets.

Similarly, re-rental data can shine a light on assets your fleet may be missing. What equipment have you recently paid to rent from a competitor, only to turn around and rent it out to your own customers? Is there enough demand for that specific machine that it’s worth adding to your own fleet?

Acquisition

Once you’ve decided on the specific machine(s) that you’d like to add to your fleet, it’s time to move to the next stage: acquisition. Strategically managing your procurement process can help you make the most of your equipment budget, while proper planning and set-up makes the upcoming rental stage run more smoothly.

In the acquisition phrase, consider:

- Is buying new better in terms of reliability and/or warranty, or does buying used fill your need at a lower price point?

- Can you purchase directly from your preferred dealer or are there other potential hoops to jump through?

- Can you get bulk pricing if you purchase several of the same machine?

- Does your corporate leadership team prefer that you purchase the majority of your fleet from a few select brands, either for the sake of preferential pricing or familiarity within your service department?

- Will you need to start with a Request for Quote (RFQ) or can you go directly to the manufacturer with a Purchase Order (PO)?

Your paperwork may need to go through several rounds of approvals, especially for higher-dollar-value machine purchases. Once complete, the details should be entered into your system of record, where you can track the status of the purchase and its anticipated delivery date.

Post-Acquisition Equipment Setup and Accounting

Once you’ve received, inspected, and accepted the machine, you can officially add it to your rental inventory. Assuming it’s a serialized asset, add the serial number, warranty information, purchase price, and other pertinent details to your rental software. Make sure to follow your company’s standard naming conventions to keep your data as clean as possible.

From there, it’s time to shift your focus to the logistics of managing your new machine. Who gets the sales reps up to speed on the new specs? What service do you need to get on the schedule now to make sure you meet the terms of your warranty? Are there safety sheets that you need to upload and have each new customer sign when they rent out the machine? How do you intend to have your accounting team manage depreciation? These key considerations should be discussed before you start renting out the new equipment.

Use (Rental)

Congratulations: you’re the proud owner of a new piece of equipment! Time to go get it out on rent.

Assuming a standard life expectancy on a new equipment purchase, this stage is the longest stage in the entire machine lifecycle. There’s the constant ebb and flow of check-outs and check-ins, extensions and exchanges, pickups and deliveries, pricing adjustments, and upkeep – which brings us to what is technically considered the fourth phase of the machine lifecycle: maintenance.

Maintenance

Maintenance may be the “fourth” stage of the machine lifecycle, but it runs concurrent to the third (rental) stage. Keeping your assets well-maintained isn’t just crucial for maintaining your reputation as a reliable rental provider; it’s essential for extending the usable lifespan of your equipment and reducing the cost of unplanned repairs.

Of course, with preventive maintenance, scheduled service, and unscheduled repairs all competing for your service techs’ attention, it can be hard to prioritize the right work at the right time. AI-driven service solutions may help your team more efficiently manage the equipment maintenance lifecycle. Essential preventive services don’t fall through the cracks, while machines that have upcoming reservations are automatically moved to the front of the line. Records are automatically linked to each machine so you have a full track record of completed work when the time comes to sell the asset.

In some cases, your accounting team may want to capitalize the cost of certain parts and labor. Your rental lifecycle management software can help automate this process so you don’t have to update your fixed asset records manually.

Disposal

Eventually, every piece of equipment reaches the end of its lifecycle. Your decision-making process may account for several different factors; you may decide that it’s no longer useful to you, or that it’s no longer usable at all.

In the case of a low-performing asset, you may want to trade it back in or sell it and recover some of your initial investment. For a heavily damaged or otherwise unsellable machine, scrapping it out for parts may be an option, or disposal may be more convenient. In either case, disposal is the last stage in the life cycle of a rental asset.

If you’re selling: First and foremost, you’ll need to determine a fair sale price. You can’t go on gut feel here; overpriced equipment will stagnate and take up valuable room in your rental yard. Make sure you’re using benchmark data that accounts for condition, local market conditions, and actual closed sale prices for your preferred sale format (auction vs. outright sale.) A broker or consigner can help with this, but for an additional fee.

In your accounting system, be sure to track the sale price, date of sale, and invoice number, halting depreciation to calculate your final gain or loss.

If you’re disposing of the unit: Is there any salvage value for the copper, steel, iron, or aluminum parts? What local or environmental regulations do you need to follow?

In either scenario: will you be replacing the machine or phasing it out entirely? If the former, be sure to build a replacement into your next planning phase…at which point your equipment management cycle has officially come full circle.

Build a Smarter Equipment Lifecycle Management Strategy

Equipment lifecycle management is hard enough when you have a handful of assets. When you’re managing hundreds or thousands, with long-term plans to scale even further? Spreadsheets and whiteboards just won’t cut it. It’s crucial to have lifecycle management software that keeps you (and your employees!) on the right track.

It’s also crucial to have an ERP system that supports your unique business processes. You know how to manage your tools and equipment – that’s why you’re in the industry you’re in. You just need a system that can keep your workflows on track as you move through the stages of the equipment lifecycle.

InTempo Enterprise helps you track and manage the entire lifecycle of every rental asset in your fleet, from pre-purchase planning to sale or disposal. Learn more about our equipment lifecycle solutions here, or contact us today to request a demo.

Faith Kubicki

Faith Kubicki