Interview with Justin Taylor of B&G Equipment on Telematics

InTempo’s Director of Marketing Kate Miller spoke with Justin Taylor, Director of Fleet Operations at B&G Equipment & Supply in Birmingham, Alabama. Justin discussed B&G’s use of telematics software alongside InTempo Enterprise rental software.

Q: What prompted you to start using telematics software?

JT: We have four different manufacturers, and each of them had their own telematics system. There was Komatsu’s Komtrax, Caterpillar’s VisionLink, Volvo’s CareTrack and John Deere’s JDLink. Managing all of those separately was a lot to handle. We were looking for a way to funnel all the different OEM’s telematics platforms into one portal. We checked out several different software providers to do this for us and we finally decided to partner with Telogis. Telogis acts like a funnel for the different telematics platforms and allows us to generate reports and manage our fleet from one log in. Telogis also integrates the various OEM telematics data into our InTempo Enterprise rental software.

Q: Did you get started with all four systems at one time, or was it a slow process?

JT: It’s been a process. Initially manufacturers would only put telematics on larger pieces of equipment, but that’s starting to change. In the last couple of years, telematic equipped machines have been filtering down to smaller pieces of equipment as well. We have a relatively young fleet, so much of our equipment came equipped with telematics.

Q: Do you have to pay an extra fee for the system?

JT: Some OEMs may provide it at no charge, but that’s not common. You can negotiate price along with the equipment purchase. Different dealers and manufacturers have different policies. For some it is free for three years, then you pay an annual fee to continue to use the telematics.

Q: Does Telogis provide benefits aside from a streamlined interface?

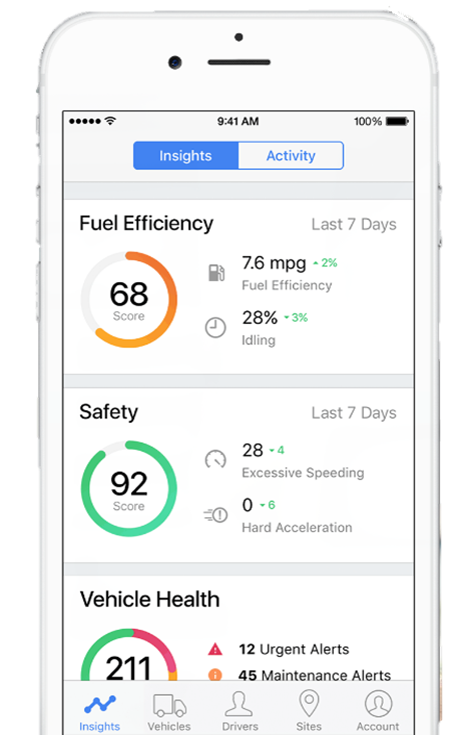

We use it for reporting. We provide a report to our UPI (utility, power and infrastructure) group, which is a large consumer of earth moving equipment. It is important for the managers in that group to understand fuel consumption and utilization of the larger pieces of equipment. What Telogis does is impressive—they have built a custom report that contains the data points that our estimators, project managers, and field supervision are looking for. Telogis is integrated with our equipment rental software, InTempo Enterprise, so we can see data such as location and current equipment hours.

image from telogis.com

Q. Have you run into any challenges?

JT: There’s a group called the Association of Equipment Management Professionals (AEMP) that works in conjunction with all the different major equipment manufactures to standardize data elements. The first version of AEMP Telematics Standard was published in 2010, and they just came out with a new standard that includes 19 new data fields, up from 5 in the original version. When the equipment manufacturers adopt AEMP 2.0, we’ll be able to take better advantage of Telogis since we’ll be able to populate all of the data points we need, regardless of equipment manufacturer or the telematics device being used. It is my understanding AEMP 2.0 will be implemented at the manufacturer level during the first half of 2017.

Q: Have you seen any changes or benefits since you started using telematics systems?

JT: The possibilities with telematics are only limited by your imagination and willingness to get outside the box. You can monitor utilization and fuel consumption, you can lower your operating costs. You can also minimize down time. We receive maintenance notifications so we’re able to avoid major costly repairs before they happen. You’ll receive notifications that a machine has been serviced—you get an email and a message appears in the Telogis interface. There’s a predictive element you can benefit from as well. Another huge advantage is safety and security, since the technology allows you to see the location of a piece of equipment with breadcrumb trails. Our safety department is definitely interested in this because they can utilize the trails to understand where a machine is operating relative to pedestrian traffic on a jobsite. We can also put geofences around a piece of equipment at a job site and it can tell you when a machine leaves or enters the denoted area. That’s so important from a safety perspective.

Q: Was there a moment where you realized the potential of this technology?

JT: the first time I was really taken back by the technology was about three years ago. My office was next to our where our field service dispatcher sat. We had a piece of equipment that was on a project that was very close to our shop. I was sitting at my desk working and got an email that came through with an engine overheat fault code. I immediately recognized which machine it was. I finished reading the email, and at that moment I heard my field service dispatcher get a phone call and it was the superintendent that was renting that piece of equipment. He said he just blew the radiator hose and asked for us to send a mechanic. But I knew about it even before our field service guy got the call. That was the first moment I realized the magnitude of what the technology can do.

Q: Do you have any advice for other businesses thinking about using telematics?

With telematics, the analogy that is commonly used in the industry is that it can be like drinking through a firehouse. There’s so much information available, and a lot of companies are maybe intimidated by that. But my advice is to figure out what’s important to you and embrace the technology. A consistent message I’ve heard from going to conferences on this topic is that companies are integrating telematics into their processes from top to bottom—they’re using the information to get a bid day advantage. Telematics is allowing people to see how much their equipment idles, which there was really no way to accurately measure before. There are times when equipment will idle as part of the operation, but nonproductive idle time is very important for businesses like ours because service intervals, leases, and warranties are based on hours. When you go to sell the equipment, the first thing the buyer is going to look at is how many hours are on the machine. It’s not uncommon to see some pieces of equipment with up to 70% idle time. If you are moving dirt and you have high idle time on your trucks and very low idle time on your excavator, that means you probably need to add a truck, and vice versa. If you don’t adopt and embrace the technology, your competitors will and they’ll have the advantage come bid day.