5 Strategies for Prioritizing Maintenance Work Orders

Keeping a rental fleet running isn’t just about fixing what’s broken - it’s about constantly deciding what should be fixed first

and why. When dozens of work orders are competing for limited shop hours, technicians, and upcoming rental commitments, the difference between a good system and a great one is how well it handles prioritization.

Understanding Work Order Priorities

Every maintenance team must balance their priorities when multiple pieces of equipment need attention, but resources are limited. Having a system that tracks equipment status in real time helps teams visualize which machines are down, which are on rent, and which require urgent attention.

With this visibility, you can make informed choices, rather than reacting to every new request as it comes in. Prioritization isn't just about speed; it's about impact.

Key Strategies for Prioritization

Here are some practical strategies teams use to stay ahead:

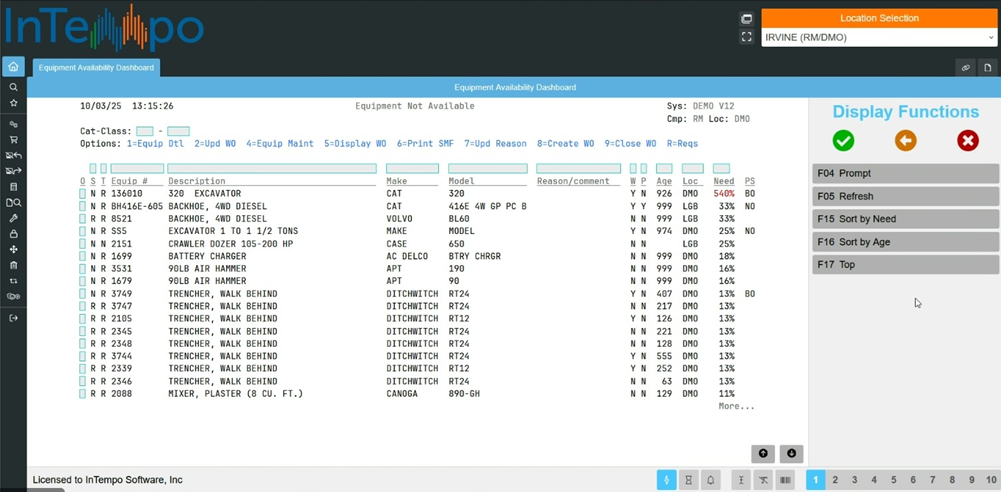

1. Use an Equipment Availability Dashboard to Track Equipment Statuses in Real Time

Stop guessing what’s down – or trying to track it on a whiteboard on the wall of the shop. An effective dashboard highlights which machines are down, the duration of downtime, and its potential impact on operations. This helps managers quickly identify high-priority work orders.

2. Use Categorization to Guide Decisions

Assign categories to work orders based on urgency and operational impact—such as safety-critical, high-use, or on-rent equipment. (Better yet – don’t do this manually; let a tool like Service Solution prioritize work orders for you.) Is a down unit needed for an upcoming reservation? Is a machine that’s currently on rent about to become a safety liability? Do you have three other machines of the same cat/class waiting in the yard in case a new reservation comes in? Data-driven categorization allows managers to decide which tasks will keep operations running smoothly while scheduling lower-priority work efficiently.

3. Apply the Same Concept to Field Service

Optimize field service operations in the equipment rental industry with CSX. By leveraging intelligent routing, real-time GPS tracking, and drag-and-drop scheduling, CSX enables service managers to dispatch technicians more efficiently for both planned preventative maintenance and unexpected repairs. This integration, combined with configurable workflows, can help reduce technician drive time, boost response rates, and ultimately provide faster, more reliable field service to customers.

4. Keep Communication Simple and Clear

Maintenance isn’t just about fixing equipment; it’s about teamwork and collaboration. Make sure your team has easy access to the same work order data, so everyone from shop managers to field technicians understands what needs attention first.

5. Adjust and Repeat

Priorities will continuously change. Equipment usage, upcoming jobs, and unexpected breakdowns all affect what should come next. Regularly review your work orders and adjust priorities to match real-world conditions.

How InTempo Can Help You Manage Your Work Orders More Efficiently

At InTempo Software, we help rental and transport operators stay connected, informed, and ahead of the game. Efficient maintenance prioritization isn’t just a nice-to-have—it’s a critical part of running an efficient rental operation. To see our work order solutions in action, contact us today.

Arielle Cox

Arielle Cox